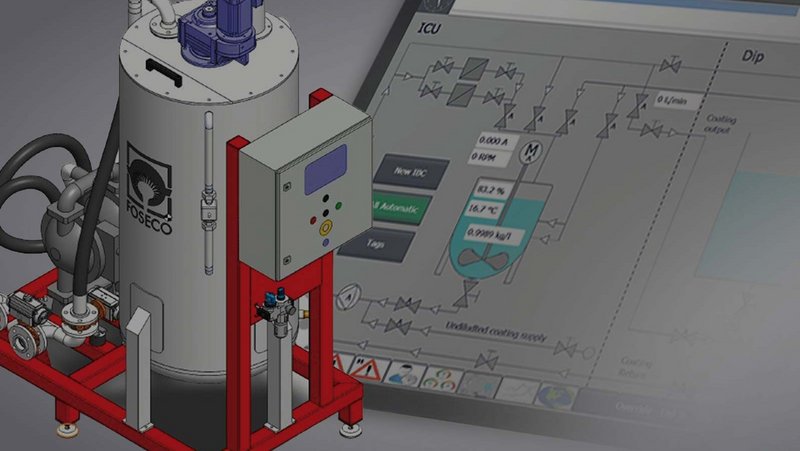

Wherever you are in the world, expert advice is always just a phone call away. Our technical specialists will be delighted to provide application advice, conduct process audits and deliver training that’s designed to maximise the benefits our solutions create.