Casting defects can significantly undermine the quality and performance of metal castings. For foundry professionals, issues like shrinkage in casting, gas porosity, non-metallic inclusions, and surface erosion translate into costly rework, scrap, and lost productivity. Fortunately, advanced foundry solutions are available to combat these problems at the source. Foseco – as a leading provider of foundry consumables – offers a range of products designed to reduce defects and ensure sound, high-quality castings.

Foundry professionals must employ the right techniques and products to prevent defects at the source as each of these defects can dramatically affect casting quality. A shrinkage cavity hidden inside a casting could cause a leak or failure under stress, gas porosity can lower strength and ductility, inclusions can act as crack initiation sites, and surface defects increase rejection rates due to cosmetic or tolerance issues.

Feeding systems to eliminate shrinkage in casting

As metals solidify, they shrink in volume causing shrinkage, which can leave internal voids or cavities if not properly fed with extra metal. This defect often appears as pockets or sponge-like porosity (shrinkage porosity) in thicker sections of a casting. Shrinkage defects weaken the casting and can cause leaks in pressure-tight components.

Shrinkage defects in casting are best prevented by feeding – supplying liquid metal to compensate for shrinkage as the casting solidifies. Foseco is renowned for its feeding system products (risers and feeder sleeves) that ensure sound castings free of shrinkage cavities. These products control shrinkage in casting and optimise yield for iron, steel, and aluminium alloys.

- Exothermic and insulating feeder sleeves. Foseco’s feeder sleeves (such as the FEEDEX range) are placed on risers to keep the feed metal liquid longer. They contain exothermic materials that release heat or insulating materials that reduce heat loss, so the feeder solidifies last – feeding shrinkage in the casting effectively. This avoids shrinkage porosity in the mould cavity and boosts yield (since smaller feeders can do the job). By using high-performance sleeves, foundries can achieve very high feeding efficiency, preventing shrinkage defects while reducing excess metal requirements. For example, FEEDEX sleeves are designed to spot-feed hot spots on iron castings, ensuring even the smallest casting sections are sound and free of shrinkage voids.

- High-yield feeder designs. Modern Foseco feeder designs focus on maximising yield and ease of use. Options like spot feeders and low-contact feeders feed isolated sections without needing large reservoirs of metal. Feeder sleeves with integrated breakers or knock-off features make it easy to remove the feeder post-solidification, leaving a clean casting. All these features encourage use of feeders at every necessary location, thereby eliminating internal shrinkage porosity. As a result, foundries pour sound castings for less money by controlling shrinkage and optimising yield which speaks to both quality and cost-effectiveness.

- Direct-pour technology (KALPUR). Foseco’s innovative KALPUR direct-pour technology combines a feeding system with filtration. A KALPUR unit replaces a traditional feeder and pour basin – molten metal is poured through a ceramic foam filter embedded in the feeder. This design calms the metal flow and removes inclusions, then acts as a feeder to supply hot metal during solidification. The dual benefit is eliminating turbulence (preventing re-oxidation) and feeding the casting, which reduces the risk of shrinkage casting defects. In essence, one KALPUR unit can both purify metal and ensure directional solidification, resulting in castings that are free of shrinkage cavities and inclusions. Such systems simplify rigging design and can often raise productivity by allowing pouring directly into a feeder without gating systems.

By deploying the right feeding system for each application – whether an insulating sleeve on a hefty steel casting or an exothermic spot feeder on a thin-section iron part – foundries can virtually eliminate shrinkage-related scrap. Foseco’s feeding specialists and riser design software (part of its technical services) further assist in optimising feeder size and placement for total shrinkage porosity control. The investment in quality feeders pays off in the form of reliable castings and higher yield of metal poured.

Melt treatment to prevent gas porosity

Gas porosity refers to small holes or pores in the metal caused by trapped gas. In aluminum alloys, hydrogen gas is the main culprit – molten aluminum readily absorbs hydrogen from moisture (water vapor) in the environment. As the metal cools, its hydrogen solubility drops drastically, causing the hydrogen to come out of solution and form tiny gas bubbles dispersed through the casting. These pores may be microscopic, but they act as points of weakness and can mar machined surfaces. Gas porosity reduces mechanical strength and can lead to poor surface appearance or blisters.

Gas porosity, especially from dissolved hydrogen in aluminum alloys, demands a proactive melt treatment approach. Foseco provides both equipment and chemical products to remove gases and prevent porosity before the metal even reaches the mould. Foundry professionals can employ these solutions to achieve clean, gas-free melts.

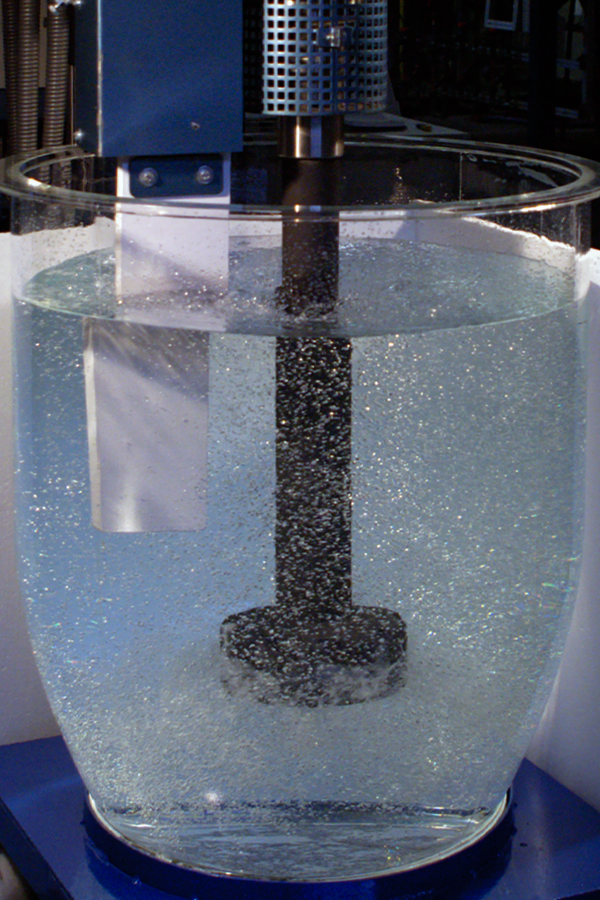

- Rotary degassing equipment: Foseco’s FDU (Foundry Degassing Unit) is an automated rotary degassing system that injects an inert gas (nitrogen or argon) via a spinning rotor into molten aluminum. This process strips out dissolved hydrogen by diffusing inert gas bubbles through the melt. The FDU process is highly efficient and consistent, reducing hydrogen content to safe levels in a matter of minutes. By minimising hydrogen, the primary cause of gas porosity is addressed – ensuring that as the casting solidifies, there is little to no hydrogen available to form bubbles. Foseco even offers SMARTT Degassing software to optimise the degassing cycle based on melt conditions, ensuring reliable results for hydrogen removal every time.

- Fluxes to reduce hydrogen pick-up: Chemical fluxes play a crucial role in aluminum melt treatment. Foseco’s covering and cleaning fluxes (such as the COVERAL range) form a protective molten layer on top of the melt. This molten slag cover serves two purposes: it prevents further oxidation of the molten metal and stops contact with moisture (thus preventing hydrogen gas pick-up from the atmosphere). In addition, these fluxes agglomerate oxides and non-metallic inclusions, collecting them into a clean dross for easy removal. The resulting dross is metal-free, meaning fewer aluminum oxides remain to generate gas. By using the proper flux, foundries can both protect the melt and reduce existing inclusions, tackling two defect sources at once (gas and inclusions).

- Grain refinement and modification: Although not directly about porosity, treating the melt with grain refiners (like Foseco’s NUCLEANT tablets or TIBORAL rods) can indirectly help feeding and reduce shrinkage porosity in aluminum castings. A finer grain structure means a more uniform solidification, which improves feeding and can reduce localised shrinkage that might otherwise appear as shrinkage porosity. Additionally, better grain structure improves mechanical properties, allowing castings to tolerate small porosity better. This is a complementary measure alongside degassing.

By implementing Foseco’s melt treatment solutions, foundries can significantly cut down on gas-related defects. Think of it as “scrubbing” the melt clean: remove the invisible hydrogen and your aluminum casting won’t suffer the blisters or air holes that plague untreated melts. In fact, industry studies and practice show that porosity is usually either hydrogen-based or shrinkage-based in origin – Foseco’s degassing and feeding solutions tackle both mechanisms. The result is dense, pressure-tight castings with high integrity. Foundry professionals will notice improved mechanical properties and far fewer rejects due to porosity once proper degassing and melt protection fluxes are in use. Machining yields also improve, since there are no hidden gas pockets to cause tool chatter or surface pits.

Filtration and inclusion removal for cleaner castings

Non-metallic impurities that become trapped in the solidifying metal are called inclusions. They often come from slag or dross – the oxidised compounds and dirt that form on molten metal. Slag can originate in the furnace from oxidation of elements and even from refractory erosion or sand in the charge. Dross is a similar layer of oxides/impurities that forms on aluminum or magnesium alloys. If not removed, pieces of slag or dross can flow into the mould cavity, solidifying as inclusions. Inclusions act as internal flaws and cause machining issues as well as surface blemishes. Turbulent metal flow during pouring can further abrade mould or furnace linings, dislodging particles that become inclusions.

Controlling the flow and cleaning the melt to remove molten slag and dross is critical to avoid these trapped impurities. Inclusion defects (from slag, dross, or sand) are addressed by Foseco through filtration and flow control systems, as well as techniques to remove slag/dross before pouring. Key strategies and products include:

- Ceramic Foam Filters: Placing a ceramic foam filter in the gating system is a proven way to capture slag and oxide inclusions before they enter the mould cavity. Foseco’s STELEX® ceramic foam filters (available as filters for iron castings, filters for steel castings, and filters for non-ferrous alloys) have a precisely engineered pore structure that traps inclusions and smooths metal flow. By filtering the metal, you can significantly reduce inclusions and also lower turbulence, as it often is the case in green sand casting. Reduced turbulence means less re-oxidation of the metal as it fills, which further prevents new inclusions from forming. Foseco filters are designed with excellent flow characteristics, so they do not cause misruns yet are highly effective at scrubbing the metal stream. Foundries that adopt filtration often see dramatic improvements in casting cleanliness and a reduction in x-ray defects for critical castings.

- Slag and dross removal practices: In the melt shop, Foseco’s range of fluxes and treatment agents help foundries deal with slag and dross before pouring. For instance, a covering flux not only prevents oxidation but also forms a dross layer that can be removed easily, taking harmful impurities with it. The removed dross/slag often contains the impurities that would have become inclusions. Interestingly, once removed, some slag byproducts can even be recycled – for example, ground granulated blast furnace slag concrete is a product where blast furnace slag is processed and used in concrete to improve strength and reduce porosity. Foseco’s fluxes (like COVERAL for aluminum, or specialised slag coagulants for iron/steel) assist in this by making slag more manageable and less metal-rich.

- Optimised gating systems: Although not a physical product per se, Foseco’s technical experts often help foundries design gating systems that minimise sand erosion and avoid slag entrapment. Using downsprues, runner extensions, or ceramic foam filtration prints, the metal flow can be conditioned to be less turbulent. A gentle, well-controlled filling means the mould is less likely to be eroded (abraded) and inclusions are less likely to form. This kind of expertise, backed by simulation and trials, is part of Foseco’s support to customers – ensuring that filters and feeding aids are used to their fullest potential in an optimised system.

With these measures, inclusion defects like slag inclusions, oxide films, or dross pockets become far less frequent. By using Foseco filters and melt cleaning products, foundries produce castings that meet stringent quality standards (for aerospace or automotive safety parts, for example) with confidence.

Coatings and mould materials to improve surface quality

In sand casting processes, the mould material itself can be a source of defects. Fast-flowing liquid metal can abrade and erode the sand mould or cores, introducing sand grains into the casting (sand inclusions). They can also cause veining. Moreover, if the sand mould is not sufficiently refractory or protected, molten metal may penetrate or stick to the sand surface. This leads to penetration and burn-on defects, where a crust of fused sand adheres to the casting surface. The result is excessive surface roughness and a poor finish that often requires aggressive cleaning or machining.

To combat defects related to sand erosion, metal penetration, and poor surface finish, Foseco provides high-quality mould and core coatings as well as binder systems. These solutions ensure that the mould can withstand the metal’s heat and velocity without deteriorating, yielding castings with smooth surfaces and precise dimensions.

- Protective refractory coatings: Foseco’s sand mould and core coatings (such as the SEMCO® range) create a thin refractory barrier on the sand surface. When cores or moulds are coated with a specifically engineered coating, they are protected against metal penetration and burn-on defects. The coatings also reduce the veining and scabbing of the mould by smoothing the surface. With a proper coating, even high-velocity metal flow will not abrade the mould surface. The result is a casting with a cleaner surface that requires minimal finishing. Foseco’s coatings are available in various formulations (water-based, alcohol-based, fast-drying, etc.) to suit different metals and processes, all aimed at achieving the best possible casting surface finish efficiently.

- Improved binder systems: Another way to reduce sand-related defects is to use high-performance binders that produce strong moulds and cores with good thermal stability. Foseco offers a range of chemical binder systems (furan, phenolic urethane, inorganic, etc.) optimised to reduce gas evolution and resist erosion. For instance, a Foseco no-bake binder might be formulated for low erosion defects and good dimensional accuracy. Stronger, more heat-resistant moulds are less likely to break down when metal is poured, meaning fewer sand inclusions and better surface detail. By selecting the right binder and using Foseco’s expertise to optimise sand properties (grain size, clay content, moisture control in green sand, etc.), foundries can further diminish surface imperfections and ensure moulds peel away cleanly.

- Permanent mould coatings: For foundries doing gravity die castings or low-pressure die casting (permanent moulds), Foseco provides DYCOTE coatings which not only protect the die but also control heat transfer. These coatings can influence the surface texture and help castings release from the die without sticking. The benefit is similar: improved surface quality and avoided defects like hotspots or soldering that ruin the finish. While this is more relevant to non-sand processes, it’s part of the holistic approach to surface quality.

By employing Foseco’s coatings on sand moulds/cores, foundry professionals typically see an immediate improvement in surface roughness and overall casting appearance. The coatings, combined with solid mould design, allow foundries to consistently achieve casting surface finishes that meet the highest standards – a crucial factor for customer satisfaction in industries where appearance and precision matter.

Casting quality assured with solutions by Foseco

Foundry professionals know that quality castings begin with quality processes. By addressing shrinkage, gas porosity, inclusions, and erosion at their roots, you can ensure the castings you produce are sound, reliable, and meet your clients’ specifications. Foseco’s product portfolio – from feeder sleeves and filters to degassing systems, fluxes, and coatings – provides a toolkit for every foundry to minimise casting defects effectively.

Unlock the full potential of your foundry by leveraging these tailored products and expert support. The path to casting excellence is clear: address the causes of defects with proven solutions, and enjoy the rewards of higher yield, lower rework, and exceptional casting quality. Your journey to defect-free castings starts now, with Foseco leading the way.