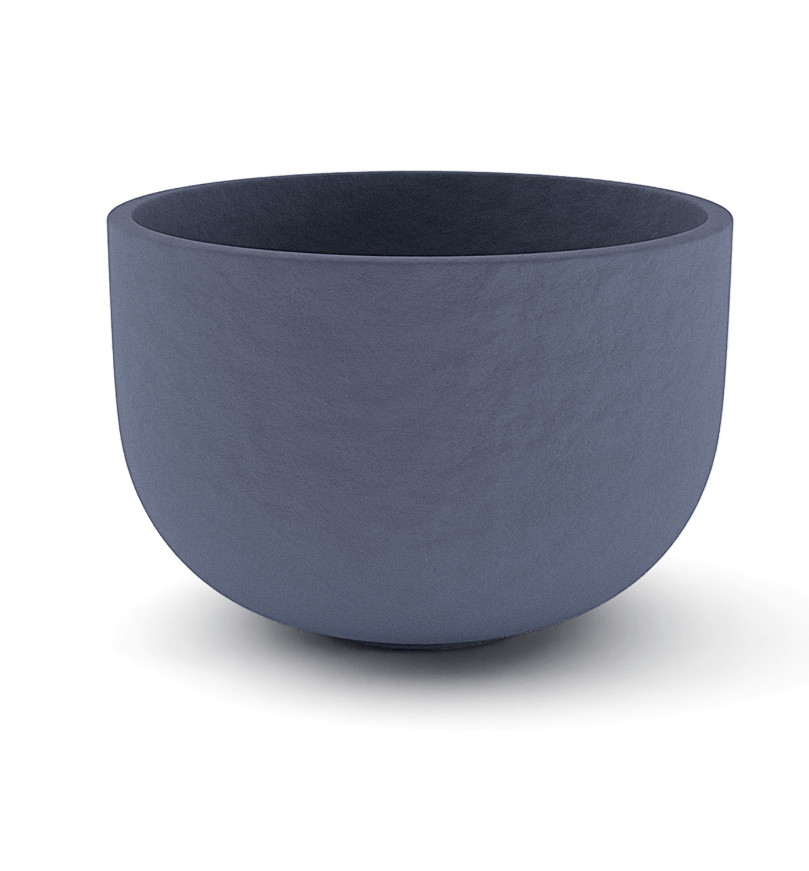

XL–Crucibles

XL – Crucibles are premium quality, high capacity, clay graphite crucibles with a high silicon carbide and graphite content that is manufactured through an advanced iso-static pressing process.

Morgan Molten Metal Systems uses a proprietary processing technology that results in a product with a very homogenous and high density structure.

This allows the crucible to obtain superior thermal conductivity over its entire operating temperature range, high mechanical strength and erosion resist-ance along with good thermal shock resistance. These properties translate into a durable and robust crucible with excellent performance characteristics.

Applications

XL - Crucibles are designed to perform exceptionally well to melt and hold aluminium and aluminium alloys in electric resistance furnaces.

Typical Metal Casting Temperature

VAluStar™ Grade: 700°C - 1000°C (1292°F - 1832°F)

Z2e² Grade: 400°C - 1100°C (752°F - 2012°F)

Performance Characteristics

- High capacity.

- Very good thermal conductivity.

- Very good resistance to chemical attack.

- Good thermal shock resistance.

- High mechanical strength and good erosion resistance.

Identification

XL - Crucibles are finished with a grey (Z2e²)/ blue (VAluStar™) Low Temperature Protection (LTP) coating.

Pattern Range

| B SF ISO | ZYL SYNCARB | |||||

|---|---|---|---|---|---|---|

| Size | H (mm) | D (mm) | d (mm) | H (mm) | D (mm) | d (mm |

| 1525 | 1050 | 1525 | 650 | |||

| 1450 | 1450 | 1270 | 1160 | |||

Contact us for a specific recommendation based on your requirements.

Quality

XL-Crucibles are manufactured from premium grade raw materials under an ISO 9001:2015 quality management system.