Foundry Practice 273

14 Jun 2023

Welcome to this edition of foundry practice which is focused on new developments for the foundry melt shop. As always Foseco aim to provide new products and processes that can increase the quality of castings produced or to reduce their cost and both wherever possible.

In this issue we have significant focus on Foseco’s novel ROTOCLENE process for treating ladles of molten steel. The process builds on our many years of offering rotary treatments to the aluminium industry but adapts and builds on this to generate benefits for steel foundries. The major benefits of the process are to clean the steel, using tiny gas bubbles to float out inclusions and bifilms from the melt, and at the same time to use the powerful

stirring action of a rotor to homogenise the temperature and composition within the ladle. The benefits of this are first of all to produce very clean steel, but also to allow casting at lower temperatures giving significant benefits in feeding properties. As you will read later, there are further additional processes and benefits that can be added optionally.

We also have an article on Foseco’s offerings in the pouring nozzle market, in bottom pouring ladle applications for Steel, repetition pouring operations for cast iron and now for the production of metal powders. The article summarises our existing technologies that include multi-use nozzles and flow controlling ‘Cross-Bore’ products, but also highlights where we have new offerings in the market. These are specifically our VAPEX FOSFLOW nozzles whose diameter can be changed whilst ladles or pouring units are in service, and we also have speciality nozzles for use in the manufacture of 3D metal printing powders, at the cutting edge of new technology.

Finally we have a reminder of Foseco’s FERROLAB V equipment for thermal analysis and control of cast iron. This equipment, in conjunction with the consumables on offer from Vesuvius’s sensor and probes division allows iron foundries to measure the physical inoculation state of iron before it poured, and to ensure that it is accurately inoculated which in conjunction with standard chemical analyses can avoid many common problems such as carbide formation and variable shrinkage behaviour.

We hope you enjoy the issue!

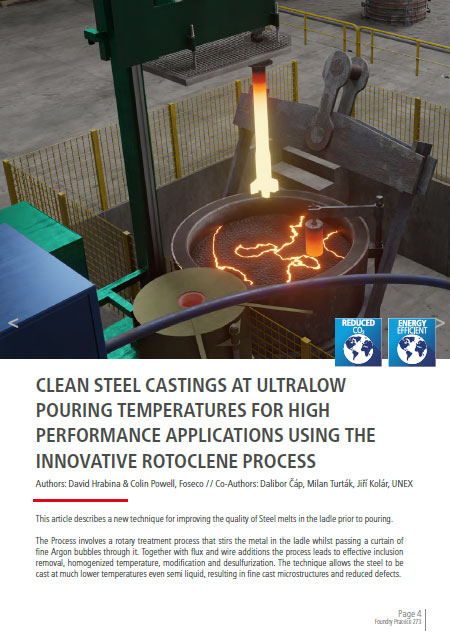

Clean steel castings at ultralow pouring temperatures for high performance applications using the innovative rotoclene process

This article describes a new technique for improving the quality of Steel melts in the ladle prior to pouring. The process involves a rotary treatment process that stirs the metal in the ladle whilst passing a curtain of fine argon bubbles through it. Together with flux and wire additions the process leads to effective inclusion removal, homogenized temperature, modification and desulfurization. The technique allows the steel to be cast at much lower temperatures even semi liquid, resulting in fine cast microstructures and reduced defects.

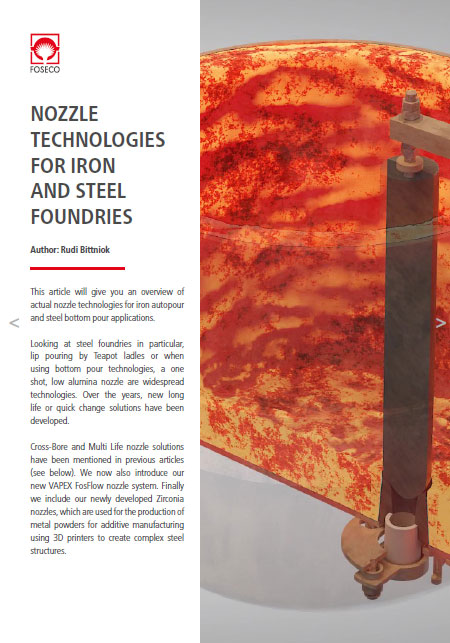

Nozzle technologies for iron and steel foundries

This article will give you an overview of actual nozzle technologies for iron autopour and steel bottom pour applications. Looking at steel foundries in particular, lip pouring by teapot ladles or when using bottom pour technologies, a one shot, low alumina nozzle are widespread technologies. Over the years, new long life or quick change solutions have been developed. Cross-bore and multi-life nozzle solutions have been mentioned in previous articles (see below). We now also introduce our new VAPEX FosFlow nozzle system. Finally we include our newly developed zirconia nozzles, which are used for the production of metal powders for additive manufacturing using 3D printers to create complex steel structures.

Increasing the consistency of iron casting properties and reducing foundry rejects by the use of FERROLAB V thermal analysis

Producing high quality iron castings requires high quality, consistent liquid iron. The quality of the liquid iron depends not only on its chemistry, but also its inoculation state – the ease of forming the physical iron structure on cooling. Thermal analysis provides a fast and cost-effective way to assess the inoculation state of liquid iron, ensuring that it can be made consistently from one batch to the next. This article describes the simple and robust device – Foseco’s FERROLAB V thermal analysis equipment. It further shows how it can be used by Romi foundry in Brazil to check, adjust and record the thermal fingerprint of each batch of iron.