Exhibits

Welcome to our exhibits section, where we will be showcasing all the exciting innovations and technologies we will be exhibiting at GIFA 2023. Our exhibits have been carefully selected to highlight the latest advances in foundry technology and metallurgy, and we can't wait to share them with you.

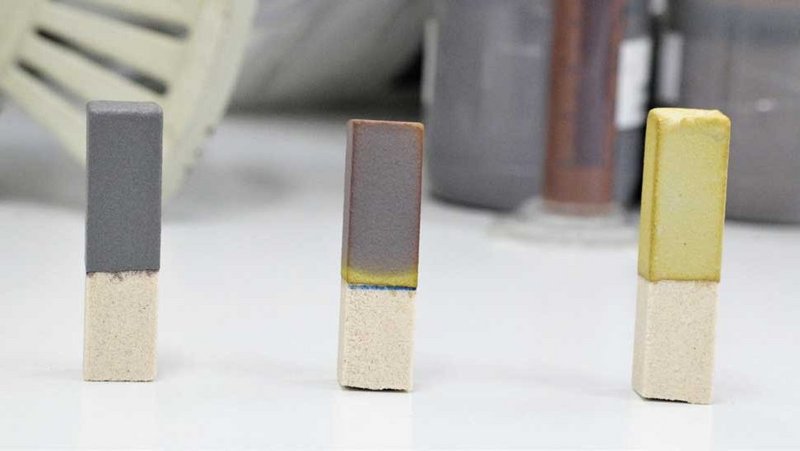

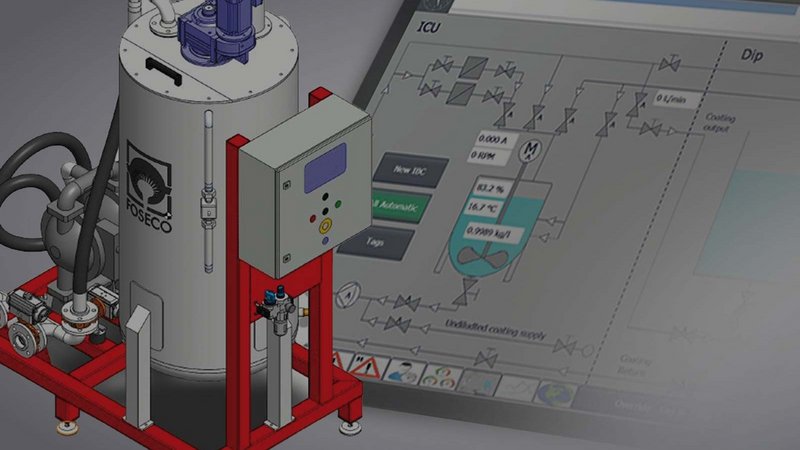

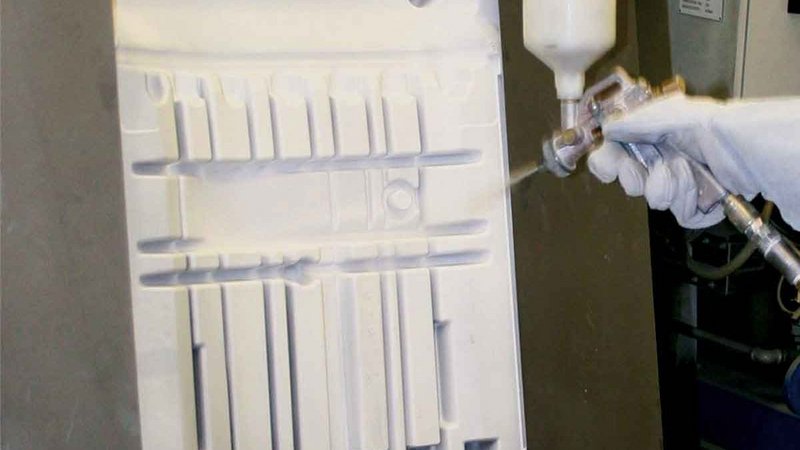

In this section you will have the opportunity to browse each exhibit in detail, with detailed descriptions, images and videos to give you a full understanding of each display. Our team has worked tirelessly to ensure that each exhibit is presented in a way that is both informative and visually appealing.

Our team of experts will be on hand to answer your questions and provide you with the information you need to make informed decisions about your foundry operations.